Document Type : Original Article

Authors

1

a Department of Materials Science and Nanotechnology, School of Science and Engineering, Sharif University of Technology, International Campus-Kish Island, Iran

2

Department of Materials Science and Engineering, Sharif University of Technology, Azadi Ave., Tehran, Iran

3

Centre for Advanced Coating Technologies, Faculty of Applied Science & Engineering, University of Toronto, 5 King’s College Road, Toronto, Ontario, M5S 3G8, Canada

Abstract

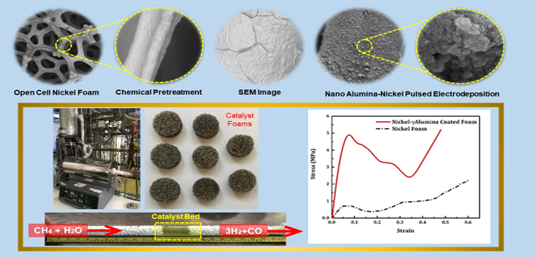

Global warming persuades researchers to improve the effectiveness of renewable energy technologies, such as H2 production by methane steam reforming (MSR) an endothermic process. Herein, a nanocatalyst based on open-cell nickel foam 40 (pore per inch) with high thermal conductivity was prepared. The nanocatalyst was synthesized with a chemical stepwise synthesis approach, chemical pre-treatment, pulsed electrocodeposition of Ni-Al2O3(γ) nanoparticles, and calcination. Measurements of thermal diffusivity(α) with flash xenon technique gained 4.41×10-6 m2s-1 and values of specific heat capacity, Cp, by differential scanning calorimetry (DSC) and thermal conductivity(λ) enhanced by 65% in temperature range of 150 to 550°C in Ni-alumina(γ) foam nanocatalyst. Furthermore, characterization and tests for comparing nickel foam and Ni-alumina(γ) foam indicated that the hardness improved from 145 Vickers hardness (HV) to 547 HV and compression strength increased from 1.1 MPa to 5MPa and specific surface area (SBET) from 1.48 m2g-1 to 48 m2g-1. XRD (x-ray diffraction) analysis showed NiO and NiAl2O4 in the structure. The interface between the catalytic component (NiAl2O4), and nickel affected the catalytic ability for MSR, and the efficiency gained at low tempreture 500 °C was the same as reported at 720°C by other investigations.

Graphical Abstract

Keywords

Main Subjects